As high-power laser technology continues to advance rapidly, Laser Diode Bars (LDBs) have become widely used in industrial processing, medical surgery, LiDAR, and scientific research due to their high power density and high brightness output. However, with the increasing integration and operating current of laser chips, thermal management challenges are becoming more prominent—directly impacting the performance stability and lifetime of the laser.

Among various thermal management strategies, Contact Conduction Cooling stands out as one of the most essential and widely adopted techniques in laser diode bar packaging, thanks to its simple structure and high thermal conductivity. This article explores the principles, key design considerations, material selection, and future trends of this “calm path” to thermal control.

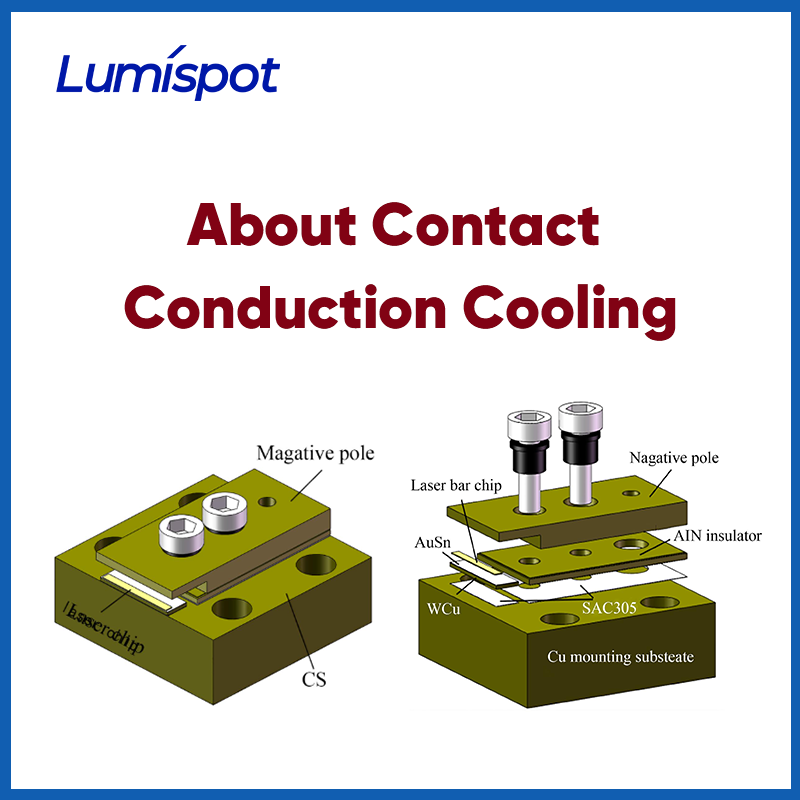

1. Principles of Contact Conduction Cooling

As the name suggests, contact conduction cooling works by establishing direct contact between the laser chip and a heat sink, enabling efficient heat transfer through high thermal conductivity materials and fast dissipation to the external environment.

① The Heat Path:

In a typical laser diode bar, the heat path is as follows:

Chip → Solder Layer → Submount (e.g., copper or ceramic) → TEC (Thermoelectric Cooler) or Heat Sink → Ambient Environment

② Features:

This cooling method features:

Concentrated heat flow and short thermal path, effectively reducing junction temperature; Compact design, suitable for miniaturized packaging; Passive conduction, requiring no complex active cooling loops.

2. Key Design Considerations for Thermal Performance

To ensure effective contact conduction cooling, the following aspects must be carefully addressed during device design:

① Thermal Resistance at the Solder Interface

The thermal conductivity of the solder layer plays a critical role in the overall thermal resistance. High-conductivity metals such as AuSn alloy or pure indium should be used, and solder layer thickness and uniformity should be controlled to minimize thermal barriers.

② Submount Material Selection

Common submount materials include:

Copper (Cu): High thermal conductivity, cost-effective;

Tungsten Copper (WCu)/Molybdenum Copper (MoCu): Better CTE match with chips, offering both strength and conductivity;

Aluminum Nitride (AlN): Excellent electrical insulation, suitable for high-voltage applications.

③ Surface Contact Quality

Surface roughness, flatness, and wettability directly affect heat transfer efficiency. Polishing and gold plating are often used to improve thermal contact performance.

④ Minimizing Thermal Path

The structural design should aim to shorten the thermal path between the chip and the heat sink. Avoid unnecessary intermediate material layers to improve overall heat dissipation efficiency.

3. Future Development Directions

With the ongoing trend toward miniaturization and higher power density, contact conduction cooling technology is evolving in the following directions:

① Multi-layer Composite TIMs

Combining metallic thermal conduction with flexible buffering to reduce interface resistance and improve thermal cycling durability.

② Integrated Heat Sink Packaging

Designing submounts and heat sinks as a single integrated structure to reduce contact interfaces and increase system-level heat transfer efficiency.

③ Bionic Structure Optimization

Applying microstructured surfaces that mimic natural heat dissipation mechanisms—such as “tree-like conduction” or “scale-like patterns”—to enhance thermal performance.

④ Intelligent Thermal Control

Incorporating temperature sensors and dynamic power control for adaptive thermal management, extending the operational life of the device.

4. Conclusion

For high-power laser diode bars, thermal management is not just a technical challenge—it’s a critical foundation for reliability. Contact conduction cooling, with its efficient, mature, and cost-effective characteristics, remains one of the mainstream solutions for heat dissipation today.

5. About Us

At Lumispot, we bring deep expertise in laser diode packaging, thermal management evaluation, and material selection. Our mission is to provide high-performance, long-lifetime laser solutions tailored to your application needs. If you’d like to learn more, we warmly welcome you to get in touch with our team.

Post time: Jun-23-2025