As high-power laser applications continue to expand, laser diode bars have become indispensable in areas such as laser pumping, industrial processing, medical equipment, and scientific research. With their excellent power density, modular scalability, and high electro-optical efficiency, these devices are at the core of many modern laser systems. Yet among the many performance indicators of a laser diode bar, one parameter is often overlooked but critically important: the divergence angle. This article explores the characteristics, physical origins, and implications of the divergence angle in laser diode bars—and how optical design can effectively manage it.

1. What Is a Divergence Angle?

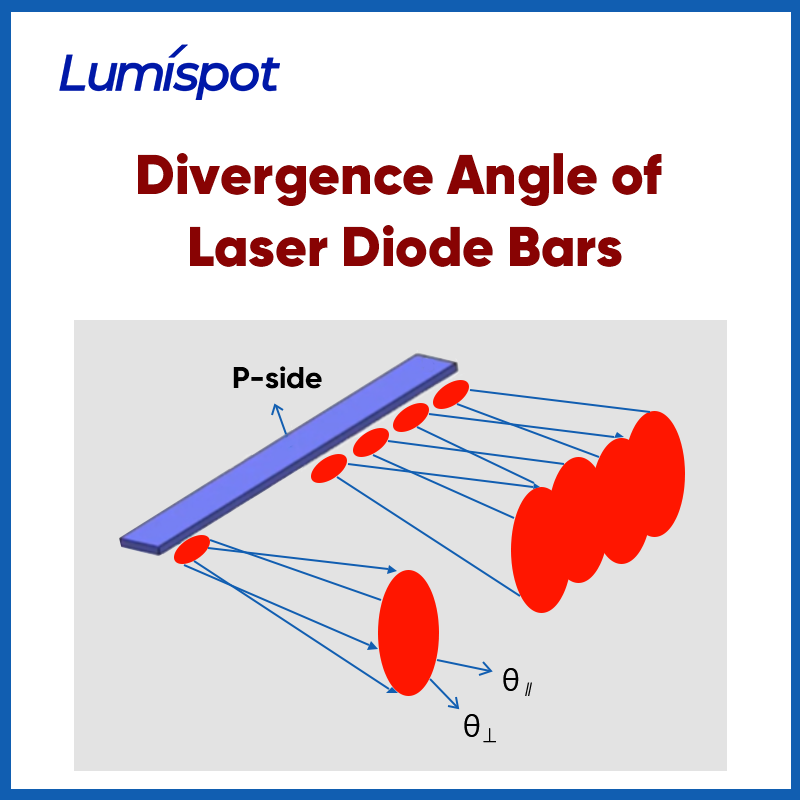

The divergence angle describes how a laser beam spreads as it propagates in free space. It indicates the extent to which the beam expands from the emission facet. In laser diode bars, the divergence angle exhibits strong asymmetry in two principal directions:

Fast Axis: Perpendicular to the bar surface. The emission region is extremely narrow (typically 1–2 µm), leading to large divergence angles, often 30°–45° or more.

Slow Axis: Parallel to the length of the bar. The emission region is much wider (hundreds of microns), resulting in smaller divergence angles, typically around 5°–15°.

This asymmetric divergence is a major design challenge for system integration involving laser diode bars.

2. The Physical Origin of Divergence

The divergence angle is primarily determined by the waveguide structure and the emission facet size:

In the fast axis, the emission area is extremely small. According to diffraction theory, smaller apertures result in larger divergence.

In the slow axis, the beam expands along the length of the bar across multiple emitters, resulting in a smaller divergence angle.

As a result, laser diode bars inherently exhibit high divergence in the fast axis and low divergence in the slow axis.

3. How Divergence Angle Affects System Design

① High Cost of Collimation and Beam Shaping

Due to the high asymmetry of the raw beam, FAC (Fast Axis Collimation) and SAC (Slow Axis Collimation) optics must be used. This increases system complexity and demands high installation precision and thermal stability.

② Limited Fiber Coupling Efficiency

When coupling laser bars into multimode fibers, optical systems, or aspheric lenses, the large fast-axis divergence can lead to beam “spillover,” reducing coupling efficiency. Divergence is a major source of optical loss.

③ Beam Quality in Module Stacking

In multi-bar stacked modules, poorly controlled divergence can cause uneven beam overlap or far-field distortion, affecting focusing precision and thermal distribution.

4. How to Control and Optimize Divergence in Laser Diode Bars

Although divergence is largely defined by the device structure, several system-level strategies can be used for optimization:

① Use of FAC Lenses

Placing a fast-axis collimation lens close to the emitting facet compresses the beam and reduces divergence in the fast axis—this is essential in most designs.

② SAC Lenses for Additional Shaping

Though the slow-axis divergence is smaller, shaping is still required in arrays or line-light sources to achieve uniform output.

③ Beam Combining and Optical Shaping Design

Using micro-lens arrays, cylindrical lenses, or structured optics can help shape multiple laser beams into a high-brightness, uniform output.

④ Device-Level Waveguide Optimization

Adjusting the active layer thickness, waveguide design, and grating structures can further refine the fast-axis divergence from the chip level.

5. Divergence Control in Real-World Applications

① Laser Pump Sources

In high-power solid-state or fiber laser systems, laser diode bars serve as pump sources. Controlling divergence—especially in the fast axis—improves coupling efficiency and beam focusing.

② Medical Devices

For systems like laser therapy and hair removal, managing divergence ensures more uniform energy delivery and safer, more effective treatment.

③ Industrial Material Processing

In laser welding and cutting, optimized divergence contributes to higher power density, better focus, and more precise, efficient processing.

6. Conclusion

The divergence angle of a laser diode bar is a crucial transition point—from micro-scale chip physics to macro-scale optical systems.

It serves as both a beam quality indicator and a design boundary for integration. As application demands and system complexity continue to rise, understanding and controlling divergence becomes a core competency for laser manufacturers and integrators alike—especially for advancing toward higher power, brightness, and reliability.

Post time: Jul-14-2025