Over the years, human vision sensing technology has undergone 4 transformations, from black and white to color, from low resolution to high resolution, from static images to dynamic images, and from 2D plans to 3D stereoscopic. The fourth vision revolution represented by 3D vision technology is fundamentally different from the others because it can achieve more accurate measurements without relying on external light.

Linear structured light is one of the most important technologies of 3D vision technology, and has begun to be widely used. It is based on the principle of optical triangulation measurement, which is claimed that when certain structured light has been projected on the measured object by the projection equipment, it will form the 3-dimensional light bar with identical shape on the surface, which will be detected by another camera, so as to obtain the light bar 2D distortion image, and to restore the object 3D information.

In the field of railway vision inspection,the technical difficulty of linear structured light application will be relatively large,because the railway career pursues some special requirements,such as large-format,real-time,high-speed,and outdoor.For example. The sunlight will have the impact on the ordinary LED structure light, and the accuracy of the measurement results, which is the common problem existed in the 3D detection. Fortunately, linear laser structure light can be the solution of the above problems, in the way of good directionality, collimation, monochromatic, high brightness and other physical characteristics. As a result, laser is usually chosen to be the light source in structured light while in the vision detection system.

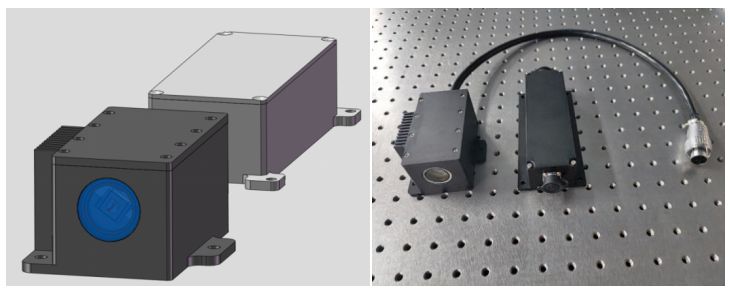

In recent years, Lumispot Tech - A Member of LSP GROUP has released a series of laser detection light source, especially a multi-line laser structured light has been released recently, which can generate multiple structural beams at the same time to reflect the 3-dimensional structure of the object at more levels. These technologies are widely used in the measurement of moving objects. At present, the main application is railway wheelset inspection.

Product Characteristics:

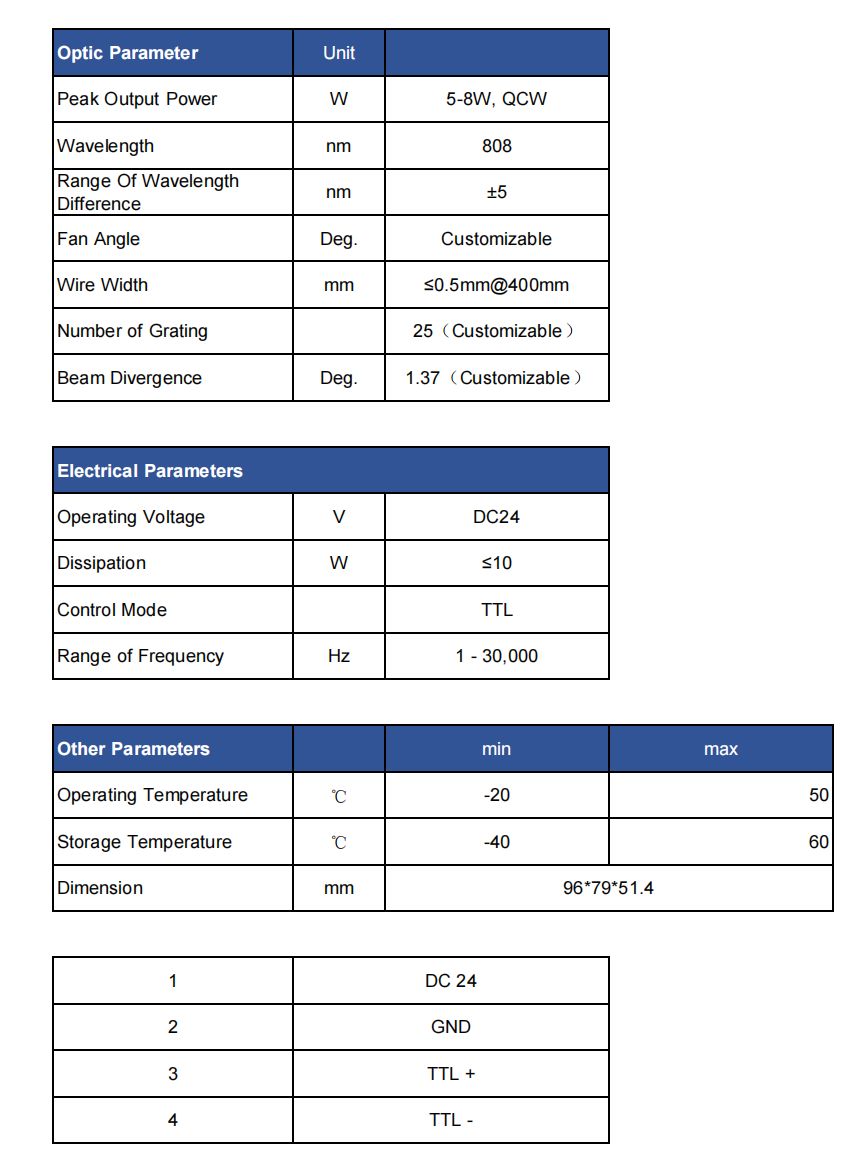

● Wavelength-- Adopting TEC heat dissipation technology, to better control the change in wavelength due to the change in temperature, 808±5nm width of spectrum can effectively avoid the influence of the sunlight on imaging.

● Power - 5 to 8 W power available, higher power provide higher brightness, the camera still can achieve imaging even in low resolution.

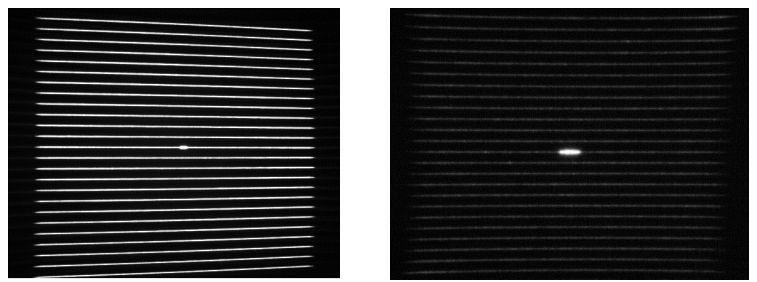

● Line Width - Line width can be controlled within 0.5mm, providing the foundation for high precision identification.

● Uniformity - Uniformity can be controlled at 85% or more, reaching the industry- leading level.

● Straightness --- No distortion in the whole spot, straightness meet the requirements.

● Zero-order diffraction--- Zero-order diffraction spot length is adjustable (10mm~25mm), which can provide obvious calibration points for camera detection.

● Working environment --- can work stably in -20℃~50℃ environment, through the temperature control module can realize the laser part 25±3℃ precise temperature control.

Fields fo Applications:

The product is used in non-contact high-precision measurement, such as railway wheelsets inspection, industrial 3-dimensional remodelling, logistics volume measurement, medical, welding inspection.

Technical indicators:

Post time: May-09-2023