Subscribe to Our Social Media For Prompt Post

In the production of precision laser equipment, controlling the environment is essential. For companies like Lumispot Tech, which focuses on producing high-quality lasers, ensuring a dust-free manufacturing environment is not just a standard—it's a commitment to quality and customer satisfaction.

What is a cleanroom suit?

A cleanroom garment, also known as a cleanroom suit, bunny suit, or coveralls, is specialized clothing designed to limit the release of contaminants and particles into a cleanroom environment. Cleanrooms are controlled environments used in scientific and industrial fields, such as semiconductor manufacturing, biotechnology, pharmaceuticals, and aerospace, where low levels of pollutants like dust, airborne microbes, and aerosol particles are crucial for maintaining the quality and integrity of products.

R&D staff in Lumispot Tech

Why Cleanroom Garments Are Needed:

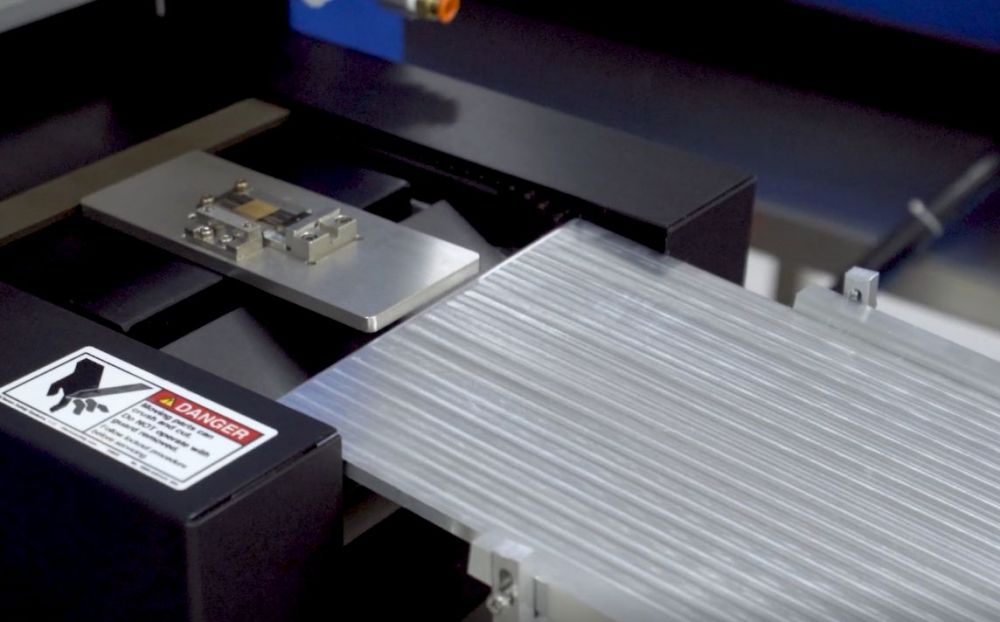

Since its founding in 2010, Lumispot Tech has implemented an advanced, industrial-grade dust-free production line within its 14,000-square-foot facility. All employees entering the production area are required to wear standard-compliant cleanroom garments. This practice reflects our strict quality management and attention to the manufacturing process.

The importance of the workshop dust-free clothing is mainly reflected in the following aspects:

The Cleanroom in Lumispot Tech

Reducing Static Electricity

Specialized fabrics used in cleanroom garments often include conductive threads to prevent the buildup of static electricity, which can damage sensitive electronic components or ignite flammable substances. The design of these garments ensures that electrostatic discharge (ESD) risks are minimized (Chubb, 2008).

Contamination Control:

Cleanroom garments are made from special fabrics that prevent the shedding of fibers or particles and resist the build-up of static electricity which can attract dust. This helps maintain the strict cleanliness standards required in cleanrooms where even minute particles can cause significant damage to microprocessors, microchips, pharmaceutical products, and other sensitive technologies.

Product Integrity:

In manufacturing processes where products are highly sensitive to environmental contamination (like in semiconductor manufacturing or pharmaceutical production), cleanroom garments help ensure that products are produced in a contamination-free environment. This is essential for the functionality and reliability of high-tech components and health safety in pharmaceuticals.

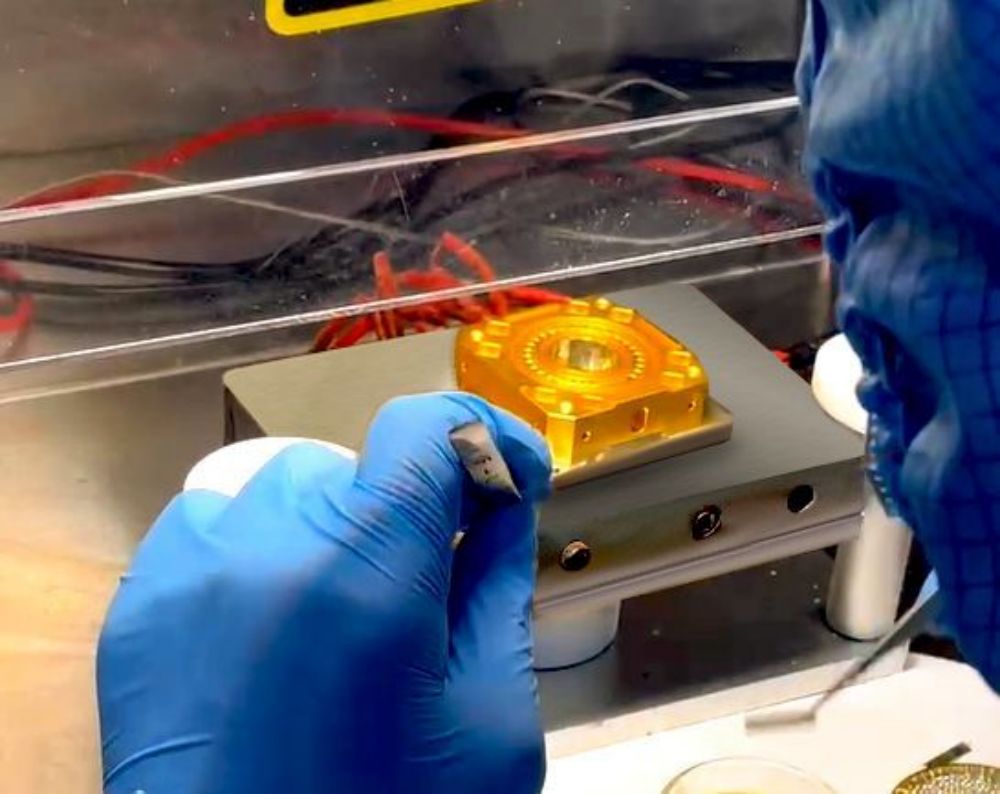

Lumispot Tech’s Laser Diode Bar Array Manufacturing Process

Safety and Compliance:

The use of cleanroom garments is also mandated by regulatory standards set by organizations such as the ISO (International Organization for Standardization) which classifies cleanrooms based on the number of particles allowed per cubic meter of air. Workers in cleanrooms must wear these garments to comply with these standards and to ensure both product and worker safety, particularly when handling hazardous materials(Hu & Shiue, 2016).

Cleanroom Garment Classifications

Classification Levels: Cleanroom garments range from lower classes like Class 10000, suitable for less stringent environments, to higher classes like Class 10, which are used in highly sensitive environments due to their superior ability to control particulate contamination (Boone, 1998).

Class 10 (ISO 3) Garments: These garments are suitable for environments requiring the highest level of cleanliness, such as the production of laser systems, optical fibers, and precision optics. Class 10 garments effectively block particles larger than 0.3 micrometers.

Class 100 (ISO 5) Garments: These garments are used in the production of electronic components, flat-panel displays, and other products that require a high level of cleanliness. Class 100 garments can block particles larger than 0.5 micrometers.

Class 1000 (ISO 6) Garments: These garments are suitable for environments with moderate cleanliness requirements, such as the production of general electronic components and medical devices.

Class 10,000 (ISO 7) Garments: These garments are used in general industrial environments with lower cleanliness requirements.

Cleanroom garments typically include hoods, face masks, boots, coveralls, and gloves, all designed to cover as much exposed skin as possible and prevent the human body, which is a major source of contaminants, from introducing particles into a controlled environment.

Usage in Optical and Laser Production Workshops

In settings such as optics and laser production, cleanroom garments often need to meet higher standards, commonly Class 100 or even Class 10. This ensures minimal particle interference with sensitive optical components and laser systems, which could otherwise lead to significant quality and functionality issues (Stowers,1999).

Staff in Lumispot Tech working on the QCW Annular Laser Diode stacks.

These cleanroom garments are made from specialized antistatic cleanroom fabrics that offer excellent dust and static resistance. The design of these garments is crucial in maintaining cleanliness. Features such as tightly fitting cuffs and ankles, as well as zippers that extend up to the collar, are implemented to maximize the barrier against contaminants entering the clean area.

Reference

Boone, W. (1998). Evaluation of cleanroom/ESD garment fabrics: test methods and results. Electrical Overstress/ Electrostatic Discharge Symposium Proceedings. 1998 (Cat. No.98TH8347).

Stowers, I. (1999). Optical cleanliness specifications and cleanliness verification. Proceedings of SPIE.

Chubb, J. (2008). Tribocharging studies on inhabited cleanroom garments. Journal of Electrostatics, 66, 531-537.

Hu, S.-C., & Shiue, A. (2016). Validation and application of the personnel factor for the garment used in cleanrooms. Building and Environment.

Post time: Apr-24-2024