Lumispot Tech also offers customization options to meet specific client needs. Interested parties are encouraged to contact Lumispot Tech for potential product development opportunities.

Subscribe to Our Social Media For Prompt Post

Lumispot Tech has established itself as a forefront innovator in the laser technology sector. Leveraging its proprietary development of a new generation of high-uniformity, high-brightness fiber-coupled semiconductor lasers, alongside its precision optical schemes designed in-house, Lumispot Tech has successfully engineered a laser system capable of delivering large field-of-view, high uniformity, and high brightness for sustained operations.

Application Scenarios of the Square Light Spot Laser

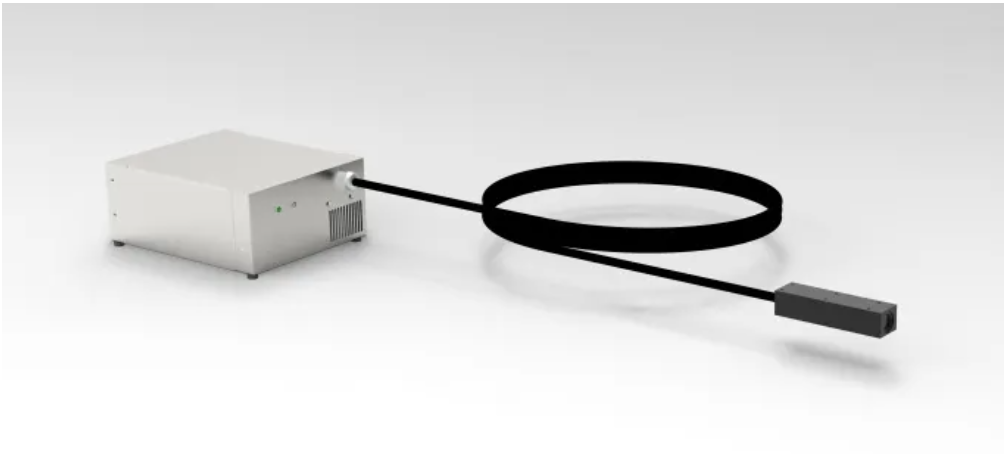

This product line represents Lumispot Tech's independently developed square-spot system, utilizing fiber-coupled semiconductor lasers as the light source. Incorporating high-precision control circuits and conveying the laser through optical fibers into an optical lens, it achieves a square-spot laser output at a fixed divergence angle.

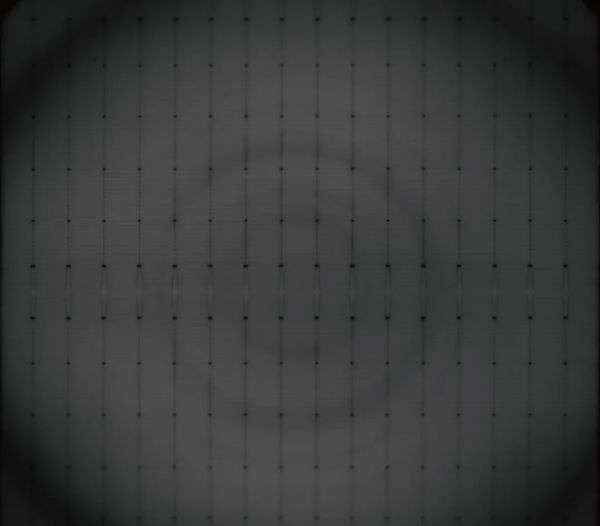

Primarily, these products are tailored for the inspection of photovoltaic (PV) cell panels, specifically in the detection of light and dark cells. During the final inspection of cell panel assemblies, Electro-Luminescence (EL) electrical testing and Photo-Luminescence (PL) optical testing are conducted to grade the assemblies based on their luminous efficiency. Traditional linear PL methods fall short in differentiating between light and dark cells. However, with the square-spot system, a non-contact, efficient, and synchronous PL inspection of different areas within the cell assembly is possible. By analyzing the imaged panels, this system facilitates the distinction and selection of light and dark cells, thereby preventing the downgrade of products due to the low luminous efficiency of individual silicon cells.

Product Features

Performance Characteristics

1. Selectable Performance and High Reliability: The system's output power is customizable, ranging from 25W to 100W to accommodate various PV cell inspection schemes. Its reliability is heightened by the use of single-tube fiber coupling technology.

2. Multiple Control Modes: Offering three control modes, the laser system allows customers to tailor control based on situational needs.

3. High Spot Uniformity: The system ensures stable brightness and high uniformity in its square-spot output, aiding in the identification and selection of anomalous cells.

| Parameter | Unit | Value |

| Max. Output Power | W | 25/50/100 |

| Central Wavelength | nm | 808±10 |

| Fiber Length | m | 5 |

| Working Distance | mm | 400 |

| Spot Size | mm | 280*280 |

| Uniformity | % | ≥80% |

| Rated Working Voltage | V | AC220 |

| Power Adjustment Method | - | RS232 Serial Port Adjustment Modes |

| Operating Temp. | °C | 25-35 |

| Cooling Method | Air Cooled | |

| Dimensions | mm | 250*250*108.5(Without lens) |

| Warranty Life | h | 8000 |

* Control Mode:

- Mode 1: External Continuous Mode

- Mode 2: External Pulse Mode

- Mode 3: Serial Port Pulse Mode

Comparative Analysis

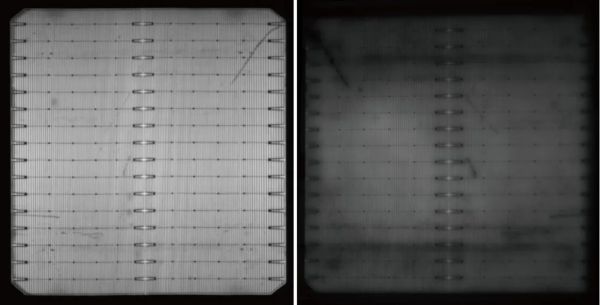

Compared to linear array detection, the area camera utilized in the square-spot system allows for simultaneous imaging and detection across the entire effective area of the silicon cell. The uniform square-spot illumination ensures consistent exposure across the cell, enabling clear visualization of any anomalies.

1. As illustrated in comparative imagery, the square-spot (area PL) method distinctly identifies dark cells that linear PL methods might miss.

2. Moreover, it also enables the detection of concentric circle cells that have progressed to the finished product stage.

Advantages of the Square-Spot (Area PL) Solution

1. Flexibility in Application: The area PL method is more versatile, requiring no movement of the component for imaging and is more forgiving of equipment requirements.

2. Discernment of Light and Dark Cells: It allows for the differentiation of cells, preventing product downgrades due to individual cell defects.

3. Safety: The square-spot distribution lowers energy density per unit area, enhancing safety.

About Lumispot Tech

As a national specialized and innovative "Little Giant" enterprise, Lumispot Tech is dedicated to providing laser pump sources, light sources, and related application systems for special fields. Among the earliest in China to master core technologies in high-power semiconductor lasers, Lumispot Tech's expertise spans materials science, thermodynamics, mechanics, electronics, optics, software, and algorithms. With dozens of international leading core technologies and key processes, including high-power semiconductor laser packaging, thermal management of high-power laser arrays, laser fiber coupling, laser optical shaping, laser power control, precision mechanical sealing, and high-power laser module packaging, Lumispot Tech holds over 100 intellectual property rights, including national defense patents, invention patents, and software copyrights. Committed to research and quality, Lumispot Tech prioritizes customer interests, continuous innovation, and employee growth, aiming to be a global leader in the specialized field of laser technology.

Post time: Mar-28-2024