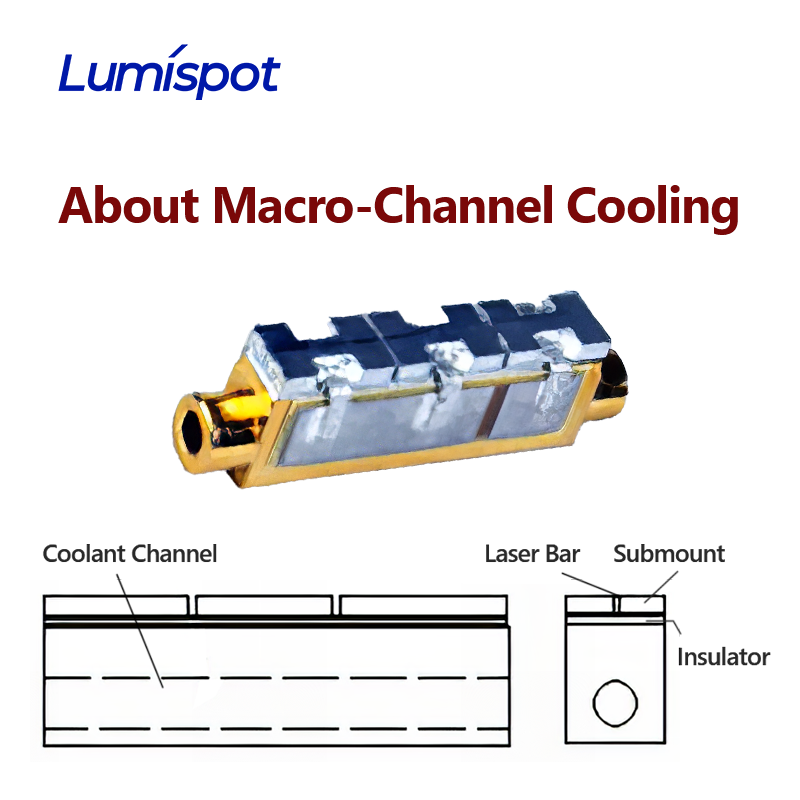

In applications such as high-power lasers, power electronic devices, and communication systems, increasing power consumption and integration levels have made thermal management a critical factor affecting product performance, lifespan, and reliability. Alongside micro-channel cooling, macro-channel cooling has emerged as a practical liquid-cooling solution. Its simpler structure, lower cost, and easier maintenance make it highly suitable for many industrial scenarios.

1. What Is Macro-Channel Cooling?

Macro-channel cooling involves the use of larger coolant flow channels (typically in the millimeter range) built into cooling plates or modules. These channels guide coolant fluids—commonly deionized water, glycol-based solutions, or other industrial coolants—through the system to remove heat generated during device operation. When integrated with a water-cooling loop, this setup enables continuous and efficient thermal control.

2. Macro-Channel vs. Micro-Channel: Key Differences

|

Feature |

Macro-Channel Cooling |

Micro-Channel Cooling |

|

Channel Size |

Millimeter-scale (1mm to several mm) |

Micrometer-scale (tens to hundreds of μm) |

|

Fabrication Complexity |

Relatively low |

Requires high-precision machining |

|

Flow Resistance |

Low, fluid flows easily |

High, needs higher pump pressure |

|

Heat Exchange Efficiency |

Moderate, suitable for medium heat flux |

High, ideal for extreme heat flux |

|

Cost |

Lower |

Higher |

|

Typical Application |

Medium-to-low heat flux, high reliability systems |

High-power density, localized heat sources |

3. Advantages of Macro-Channel Cooling

Although its thermal efficiency is lower than micro-channel solutions, macro-channel cooling offers several notable benefits:

① High reliability:

Wider channels are less prone to clogging, offering excellent long-term stability—ideal for continuous industrial operation.

② Lower manufacturing costs:

Simpler structure and diverse fabrication options make it suitable for mass production.

③ Ease of maintenance:

Long cleaning intervals, low maintenance costs, and less stringent coolant purity requirements.

④ Adequate cooling capacity:

For devices with moderate heat flux, macro-channel cooling effectively maintains optimal operating temperatures and extends device lifespan.

4. Application Scenarios

Macro-channel cooling is widely used in the following areas:

① Laser modules:

Especially for mid- to low-power or CW-mode lasers, macro-channel systems can easily handle the thermal load.

② Power electronic modules:

Such as rectifiers, DC-DC converters, and IGBT modules.

③ Power amplifiers in communication and radar systems:

Ideal for complex environments requiring long-term, stable operation.

④ Cooling systems in medical and industrial equipment:

Including semiconductor laser therapy devices, laser marking machines, and more.

5. Key Design Considerations for Macro-Channel Cooling

A successful macro-channel cooling solution requires attention to the following factors:

① Channel layout:

Should be optimized based on the device’s heat source distribution to achieve uniform cooling.

② Material selection:

Copper, stainless steel, or aluminum alloys are commonly used for their high thermal conductivity and corrosion resistance.

③ Flow rate and pump compatibility:

Proper design of fluid speed and coolant flow ensures efficient heat exchange and system stability.

④ Standardized interfaces:

Enables easy integration into customer devices or modules.

6. Conclusion

Macro-channel cooling continues to play a vital role in industrial applications due to its simplicity, reliability, and ease of maintenance. It is a cost-effective and dependable solution, especially in systems with medium to low thermal densities. As device design evolves, macro-channel solutions are also advancing toward higher integration and improved adaptability.

7. About Us

Lumispot offers extensive expertise in both macro-channel and micro-channel thermal management solutions. We provide customized cooling modules for lasers, optoelectronic devices, power electronics, and more. Our focus goes beyond thermal performance—we prioritize system integration and long-term reliability, aiming to deliver high-performance, cost-effective cooling systems.

Feel free to contact us to learn more about macro-channel and micro-channel cooling solutions tailored to your application needs!

Post time: Jun-17-2025