In modern laser applications, beam quality has become one of the most important metrics for evaluating the overall performance of a laser. Whether it’s micron-level precision cutting in manufacturing or long-distance detection in laser ranging, beam quality often determines the success or failure of the application.

So, what exactly is beam quality? How does it affect laser performance? And how can one choose the right beam quality to match specific application needs?

1. What is Beam Quality?

Simply put, beam quality refers to the spatial propagation characteristics of a laser beam. It describes how well a beam can focus, its divergence behavior, and how uniformly its energy is distributed.

In an ideal case, the laser beam resembles a perfect Gaussian beam, featuring the smallest divergence angle and the best focusing performance. However, due to factors such as source structure, material properties, and thermal effects, real-world laser beams often suffer from spreading, distortion, or multimode interference—thereby reducing beam quality.

2. Common Beam Quality Indicators

① M² Factor (Beam Propagation Factor)

The M² value is the primary parameter used to evaluate beam quality.

M² = 1 indicates a perfect Gaussian beam.

M² > 1 means the beam quality degrades, and the focusing ability worsens.

In industrial applications, M² values under 1.5 are generally required, while scientific-grade lasers aim for M² values as close to 1 as possible.

② Beam Divergence

Beam divergence describes how much the laser beam expands as it propagates over long distances.

Smaller divergence angles mean more concentrated beams, smaller focal spots, and greater precision over longer distances.

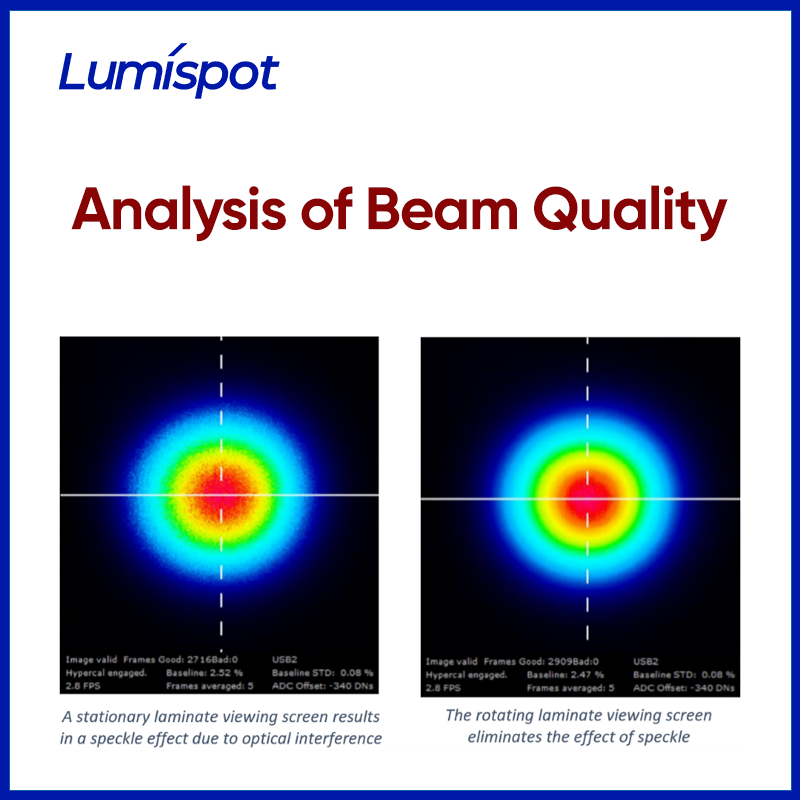

③ Beam Profile and Energy Distribution

A high-quality beam should have a symmetric, uniform beam profile with a high-intensity center. This ensures clear and controllable energy output for cutting, marking, and other applications.

3. How Beam Quality Affects Real-World Applications

① Precision Processing (Cutting/Welding/Marking):

Beam quality determines focal spot size and energy density, impacting machining accuracy and efficiency.

② Medical Lasers:

Beam quality affects how accurately energy is delivered to tissue and how well thermal diffusion is controlled.

③ Laser Ranging / LIDAR:

Beam quality directly influences detection range and spatial resolution.

④ Optical Communication:

Beam quality affects signal mode purity and bandwidth capacity.

⑤ Scientific Research:

Beam quality ensures coherence and stability in interference or nonlinear optical experiments.

4. Key Factors Affecting Beam Quality

① Laser Structure Design:

Single-mode lasers usually offer better beam quality than multi-mode lasers.

② Gain Medium & Resonator Design:

These influence mode distribution and beam stability.

③ Thermal Effect Management:

Poor heat dissipation can lead to thermal lensing and beam distortion.

④ Pump Uniformity & Waveguide Structure:

Uneven pumping or structural defects can cause beam shape degradation.

5. How to Improve Beam Quality

① Optimize Device Architecture:

Use single-mode waveguides and symmetric resonator designs.

② Thermal Management:

Integrate efficient heat sinks or active cooling to reduce thermally induced beam distortion.

③ Beam-Shaping Optics:

Apply collimators, spatial filters, or mode converters.

④ Digital Control & Feedback:

Employ real-time wavefront detection and adaptive optics to achieve dynamic correction.

6. Conclusion

Beam quality is more than just a physical parameter—it’s the “precision code” of a laser’s performance.

In real-world applications, high beam quality can significantly enhance the efficiency, accuracy, and reliability of laser systems. For users seeking high performance and consistency, beam quality should be a key consideration when selecting a laser.

As laser technology continues to evolve, we can expect better beam control in smaller devices and higher power densities—paving the way for new possibilities in advanced manufacturing, precision medicine, aerospace, and beyond.

Post time: Jul-22-2025