Subscribe to Our Social Media For Prompt Post

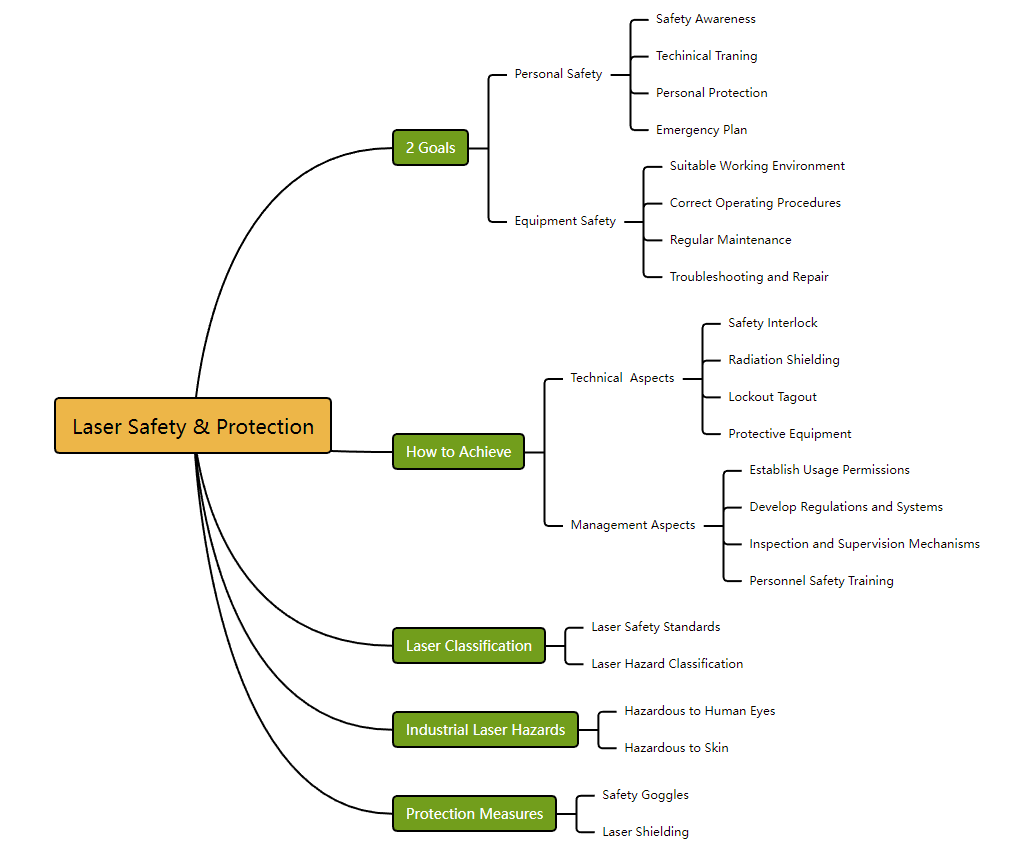

In the fast-paced world of technological advancements, the application of lasers has broadened dramatically, revolutionizing industries with applications such as laser cutting, welding, marking, and cladding. However, this expansion has unveiled a significant gap in safety awareness and training among engineers and technical workers, exposing many frontline personnel to laser radiation without an understanding of its potential hazards. This article aims to shed light on the importance of laser safety training, the biological effects of laser exposure, and comprehensive protective measures to safeguard those working with or around laser technology.

The Critical Need for Laser Safety Training

Laser safety training is paramount for the operational safety and efficiency of laser welding and similar applications. High-intensity light, heat, and potentially harmful gases produced during laser operations pose health risks to operators. Safety training educates engineers and workers on the correct use of personal protective equipment (PPE), such as protective goggles and face shields, and strategies to avoid direct or indirect laser exposure, ensuring effective protection for their eyes and skin.

Understanding the Hazards of Lasers

Biological Effects of Lasers

Lasers can cause severe skin damage, necessitating skin protection. However, the primary concern lies in eye damage. Laser exposure can lead to thermal, acoustic, and photochemical effects:

Thermal: Heat production and absorption can cause burns to the skin and eyes.

Acoustic: Mechanical shockwaves can lead to localized vaporization and tissue damage.

Photochemical: Certain wavelengths can trigger chemical reactions, potentially causing cataracts, corneal or retinal burns, and increasing the risk of skin cancer.

Skin effects can range from mild redness and pain to third-degree burns, depending on the laser's category, pulse duration, repetition rate, and wavelength.

|

Wavelength Range |

Pathological effect |

| 180-315nm (UV-B, UV-C) | Photokeratitis is like a sunburn, but it happens to the cornea of the eye. |

| 315-400nm(UV-A) | Photochemical cataract (clouding of the eye lens) |

| 400-780nm (Visible) | Photochemical damage to the retina, also known as retinal burn, occurs when the retina is injured by exposure to light. |

| 780-1400nm (Near-IR) | Cataract,retinal burn |

| 1.4-3.0 μm(IR) | Aqueous flare (protein in the aqueous humour), cataract, corneal burn

Aqueous flare is when protein appears in the eye's aqueous humor. A cataract is a clouding of the eye's lens, and a corneal burn is damage to the cornea, the eye's front surface. |

| 3.0μm-1mm | Comeal burn |

Eye damage, the foremost concern, varies based on pupil size, pigmentation, pulse duration, and wavelength. Different wavelengths penetrate various eye layers, causing damage to the cornea, lens, or retina. The eye's focusing capability significantly increases the energy density on the retina, making low-dose exposures sufficient to cause severe retinal damage, leading to diminished vision or blindness.

Skin Hazards

Laser exposure to the skin can result in burns, rashes, blisters, and pigment changes, potentially destroying subcutaneous tissue. Different wavelengths penetrate to varying depths in the skin tissue.

Laser Safety Standard

GB72471.1-2001

GB7247.1-2001, titled "Safety of laser products--Part 1: Equipment classification, requirements, and user's guide," sets forth regulations for the safety classification, requirements, and guidance for users regarding laser products. This standard was implemented on May 1, 2002, aiming to ensure safety across various sectors where laser products are used, such as in industrial, commercial, entertainment, research, educational, and medical applications. However, it was superseded by GB 7247.1-2012 (ChineseStandard) (Code of China) (OpenSTD).

GB18151-2000

GB18151-2000, known as "Laser guards," was focused on the specifications and requirements for laser protective screens used in enclosing the working areas of laser processing machines. These protective measures included both long-term and temporary solutions like laser curtains and walls to ensure safety during operations. The standard, issued on July 2, 2000, and implemented on January 2, 2001, was later replaced by GB/T 18151-2008. It applied to various components of protective screens, including visually transparent screens and windows, aiming to evaluate and standardize the protective properties of these screens (Code of China) (OpenSTD) (Antpedia).

GB18217-2000

GB18217-2000, titled "Laser safety signs," established guidelines for the basic shapes, symbols, colors, dimensions, explanatory text, and usage methods for signs designed to protect individuals from laser radiation harm. It was applicable to laser products and places where laser products are produced, used, and maintained. This standard was implemented on June 1, 2001, but has since been superseded by GB 2894-2008, "Safety Signs and Guideline for the Use," as of October 1, 2009 (Code of China) (OpenSTD) (Antpedia).

Harmful Lasers Classifications

Lasers are classified based on their potential harm to human eyes and skin. Industrial high-power lasers emitting invisible radiation (including semiconductor lasers and CO2 lasers) pose significant risks. Safety standards categorize all laser systems, with fiber laser outputs often rated as Class 4, indicating the highest risk level. In the following content, we will discuss the laser safety classifications from Class 1 to Class 4.

Class 1 Laser Product

A Class 1 laser is considered safe for everyone to use and look at in normal situations. This means you won't get hurt by looking at such a laser directly or through common magnifying tools like telescopes or microscopes. The safety standards check this by using specific rules about how big the laser light spot is and how far away you should be to look at it safely. But, it's important to know that some Class 1 lasers might still be dangerous if you look at them through very powerful magnifying glasses because these can gather more laser light than usual. Sometimes, products like CD or DVD players are marked as Class 1 because they have a stronger laser inside, but it's made in a way that none of the harmful light can get out during regular use.

Our Class 1 Laser: Erbium Doped Glass Laser, L1535 Rangefinder Module

Class 1M Laser Product

A Class 1M laser is generally safe and won't harm your eyes under normal use, which means you can use it without special protection. However, this changes if you use tools like microscopes or telescopes to look at the laser. These tools can focus the laser beam and make it stronger than what's considered safe. Class 1M lasers have beams that are either very wide or spread out. Normally, the light from these lasers doesn't go beyond safe levels when it enters your eye directly. But if you use magnifying optics, they can gather more light into your eye, potentially creating a risk. So, while a Class 1M laser's direct light is safe, using it with certain optics can make it dangerous, similar to the higher-risk Class 3B lasers.

Class 2 Laser Product

A Class 2 laser is safe for use because it operates in a way that if someone accidentally looks into the laser, their natural reaction to blink or look away from bright lights will protect them. This protection mechanism works for exposures up to 0.25 seconds. These lasers are only in the visible spectrum, which is between 400 and 700 nanometers in wavelength. They have a power limit of 1 milliwatt (mW) if they emit light continuously. They can be more powerful if they emit light for less than 0.25 seconds at a time or if their light isn't focused. However, deliberately avoiding blinking or looking away from the laser can result in eye damage. Tools like some laser pointers and distance measuring devices use Class 2 lasers.

Class 2M Laser Product

A Class 2M laser is generally considered safe for your eyes because of your natural blink reflex, which helps you avoid looking at bright lights for too long. This kind of laser, similar to Class 1M, emits light that is either very wide or spreads out quickly, limiting the amount of laser light that enters the eye through the pupil to safe levels, according to Class 2 standards. However, this safety only applies if you're not using any optical devices like magnifying glasses or telescopes to view the laser. If you do use such instruments, they can focus the laser light and potentially increase the risk to your eyes.

Class 3R Laser Product

A Class 3R laser requires careful handling because while it's relatively safe, looking directly into the beam can be risky. This type of laser can emit more light than is considered completely safe, but the chance of injury is still considered low if you're cautious. For lasers that you can see (in the visible light spectrum), Class 3R lasers are limited to a maximum power output of 5 milliwatts (mW). There are different safety limits for lasers of other wavelengths and for pulsed lasers, which might allow higher outputs under specific conditions. The key to using a Class 3R laser safely is to avoid directly viewing the beam and to follow any safety instructions provided.

Class 3B Laser Product

A Class 3B laser can be dangerous if it directly hits the eye, but if the laser light bounces off rough surfaces like paper, it's not harmful. For continuous beam lasers that operate in a certain range (from 315 nanometers up to the far infrared), the maximum allowed power is half a watt (0.5 W). For lasers that pulse on and off in the visible light range (400 to 700 nanometers), they shouldn't exceed 30 millijoules (mJ) per pulse. Different rules exist for lasers of other types and for very short pulses. When using a Class 3B laser, you usually need to wear protective glasses to keep your eyes safe. These lasers also have to have a key switch and a safety lock to prevent accidental use. Even though Class 3B lasers are found in devices like CD and DVD writers, these devices are considered Class 1 because the laser is contained inside and can't escape.

Class 4 Laser Product

Class 4 lasers are the most powerful and dangerous type. They are stronger than Class 3B lasers and can cause serious harm like burning skin or causing permanent eye damage from any exposure to the beam, whether direct, reflected, or scattered. These lasers can even start fires if they hit something flammable. Because of these risks, Class 4 lasers require strict safety features, including a key switch and a safety lock. They are commonly used in industrial, scientific, military, and medical settings. For medical lasers, it's crucial to be aware of safety distances and areas to avoid eye hazards. Extra precautions are needed to manage and control the beam to prevent accidents.

Label Example of Pulsed Fiber Laser From LumiSpot

How to protect against laser hazards

Here's a simpler explanation of how to properly protect against laser hazards, organized by different roles:

For Laser Manufacturers:

They should supply not just the laser devices (like laser cutters, handheld welders, and marking machines) but also essential safety gear like goggles, safety signs, instructions for safe use, and safety training materials. It's part of their responsibility to ensure users are safe and informed.

For Integrators:

Protective Housings and Laser Safety Rooms: Every laser device must have protective housing to prevent people from being exposed to dangerous laser radiation.

Barriers and Safety Interlocks: Devices must have barriers and safety interlocks to prevent exposure to harmful laser levels.

Key Controllers: Systems classified as Class 3B and 4 should have key controllers to restrict access and use, ensuring safety.

For End Users:

Management: Lasers should be operated by trained professionals only. Untrained personnel shouldn't use them.

Key Switches: Install key switches on laser devices to ensure they can only be activated with a key, increasing safety.

Lighting and Placement: Ensure rooms with lasers have bright lighting and that lasers are placed at heights and angles that avoid direct eye exposure.

Medical Supervision:

Workers using Class 3B and 4 lasers should have regular medical check-ups by qualified personnel to ensure their safety.

Laser Safety Training:

Operators should be trained on the laser system's operation, personal protection, hazard control procedures, use of warning signs, incident reporting, and understanding the biological effects of lasers on eyes and skin.

Control Measures:

Strictly control the use of lasers, especially in areas where people are present, to avoid accidental exposure, especially to the eyes.

Warn people in the area before using high-power lasers and ensure everyone wears protective eyewear.

Post warning signs in and around laser work areas and entrances to indicate the presence of laser hazards.

Laser Controlled Areas:

Restrict laser use to specific, controlled areas.

Use door guards and safety locks to prevent unauthorized access, ensuring lasers stop working if doors are unexpectedly opened.

Avoid reflective surfaces near lasers to prevent beam reflections that could harm people.

Use of Warnings and Safety Signs:

Place warning signs on the exterior and control panels of laser equipment to indicate potential hazards clearly.

Safety Labels For Laser Products:

1. All laser devices must have safety labels showing warnings, radiation classifications, and where the radiation comes out.

2.Labels should be placed where they're easily seen without getting exposed to laser radiation.

Wear A Laser Safety Glasses to Protect Your Eyes From Laser

Personal protective equipment (PPE) for laser safety is used as a last resort when engineering and management controls can't fully reduce hazards. This includes laser safety glasses and clothing:

Laser Safety Glasses protect your eyes by reducing laser radiation. They must meet strict requirements:

⚫Certified and labeled according to national standards.

⚫Suitable for the laser's type, wavelength, operation mode (continuous or pulsed), and power settings.

⚫Clearly marked to help choose the right glasses for a specific laser.

⚫The frame and side shields should offer protection too.

It's essential to use the right type of safety glasses to protect against the specific laser you're working with, considering its characteristics and the environment you're in.

After applying safety measures, if your eyes could still be exposed to laser radiation above safe limits, you need to use protective glasses that match the laser's wavelength and have the right optical density to safeguard your eyes.

Don't solely rely on safety glasses; never look directly into a laser beam even when wearing them.

Choosing Laser Protective Clothing:

Offer suitable protective clothing to workers exposed to radiation above the Maximum Permissible Exposure (MPE) level for skin; this helps reduce skin exposure.

The clothing should be made from materials that are fire-resistant and heat-resistant.

Aim to cover as much skin as possible with the protective gear.

How to Protect Your Skin From Laser Damage:

Wear long-sleeved work clothes made from flame-retardant materials.

In areas controlled for laser use, install curtains and light-blocking panels made from flame-retardant materials coated in black or blue silicon material to absorb UV radiation and block infrared light, thus protecting the skin from laser radiation.

It's crucial to select the appropriate personal protective equipment (PPE) and use it correctly to ensure safety when working with or around lasers. This includes understanding the specific hazards associated with different types of lasers and taking comprehensive precautions to protect both eyes and skin from potential harm.

Conclusion and Summary

Disclaimer:

- We hereby declare that some of the images displayed on our website are collected from the Internet and Wikipedia, with the aim of promoting education and information sharing. We respect the intellectual property rights of all creators. The use of these images is not intended for commercial gain.

- If you believe that any of the content used violates your copyright, please contact us. We are more than willing to take appropriate measures, including removing images or providing proper attribution, to ensure compliance with intellectual property laws and regulations. Our goal is to maintain a platform that is rich in content, fair, and respects the intellectual property rights of others.

- Please contact us at the following email address: sales@lumispot.cn. We commit to taking immediate action upon receiving any notification and guarantee 100% cooperation in resolving any such issues.

Post time: Apr-08-2024