Medical Laser Dazzler

Illumination Detetcion Research

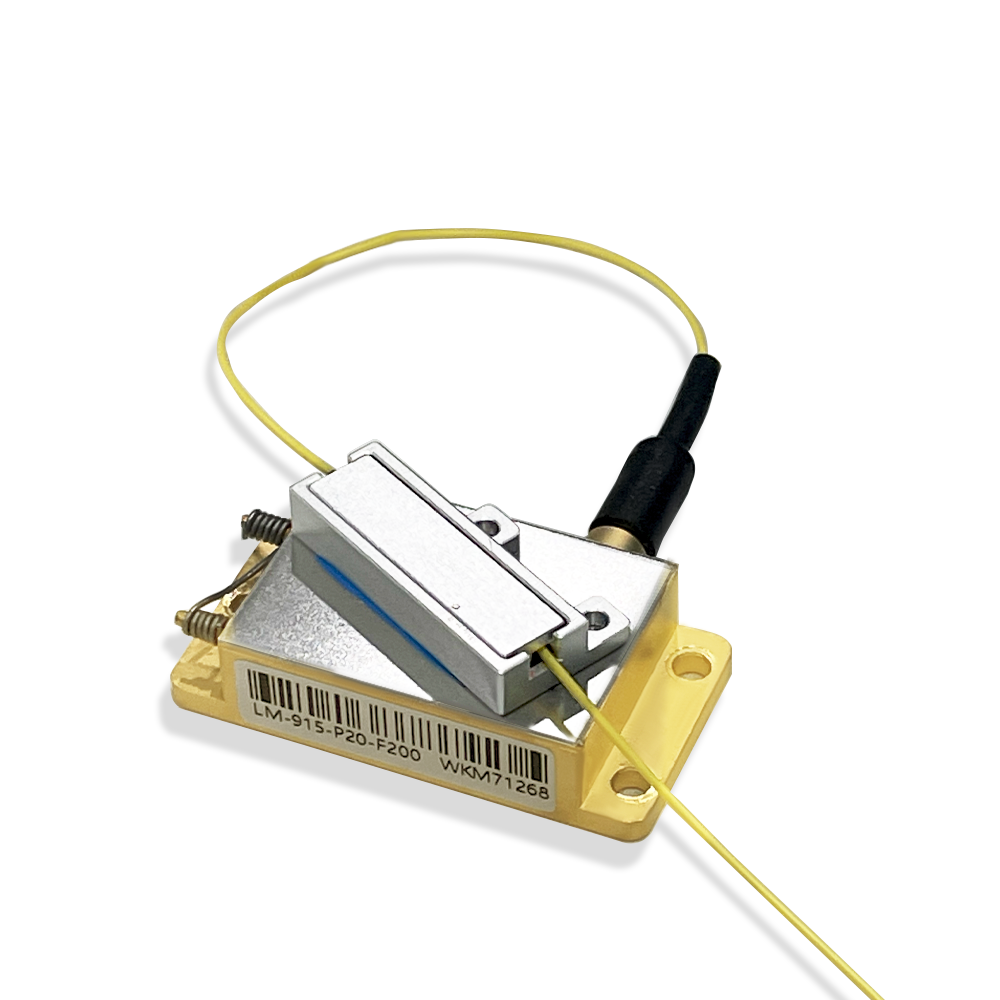

915nm Fiber Coupled Diode Laser

Specifications

| Product Name | Wavelength | Output Power | Fiber Core Diameter | Model | Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 20W | 105um | LMF-915E-C20-F105-C2-A1001 |  Datasheet Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 30W | 105um | LMF-915D-C30-F105-C3A-A1001 |  Datasheet Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 50W | 105um | LMF-915D-C50-F105-C6B |  Datasheet Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 150W | 200um | LMF-915D-C150-F200-C9 |  Datasheet Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 150W | 220um | LMF-915D-C150-F220-C18 |  Datasheet Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 510W | 220um | LMF-915C-C510-C24-B |  Datasheet Datasheet |

| Multimode Fiber-Coupled Laser Diode | 915nm | 750W | 220um | LMF-915C-C750-F220-C32 |  Datasheet Datasheet |

| Note: | It is recommended to start by selecting from the product list above. Under special circumstances, parameters such as wavelength tolerance, output power, fiber core diameter, and voltage/current can be customized. | ||||

Applications

1.Direct Semiconductor Applications

1.1 Direct Use in Medical Devices

Soft Tissue Surgery:

Working Principle: The 915nm wavelength is well-absorbed by both water and hemoglobin. When the laser irradiates the tissue, the energy is absorbed and converted into heat, achieving tissue vaporization (cutting) and coagulation (hemostasis).

Hair Removal:

Working Principle: This is an area for the direct application of 915nm lasers, the 915nm wavelength has a slightly deeper penetration, potentially making it more effective for targeting deeper hair follicles, it may also cause slightly more discomfort due to its higher absorption by water. Equipment manufacturers select the wavelength based on their specific design goals and desired clinical outcomes.

1.2 Plastic Welding

The 915nm laser diode is directly utilized as the processing source because its wavelength matches the absorption peak of plastics, offering a low system cost and sufficient power.

2.As pump source

2.1 Metal Welding: It serves as the pump source for 1064/1080nm fiber lasers, which are required for their higher beam quality essential for precision processing and ensuring weld quality.

2.2 Additive Manufacturing (Cladding): It acts as the pump source for 1064/1080nm fiber lasers, which are necessary to deliver the extremely high power and brightness needed to melt both the metal powder and the substrate.